The Microchip Shortage and Its Impact on the Global Auto Industry

The microchip shortage is currently having a significant impact on the global auto industry, as many automakers have been forced to halt production or reduce output due to a lack of semiconductor chips. The shortage is the result of a mix of factors, including increased demand for electronics and semiconductors during the COVID-19 pandemic, supply chain disruptions, and production shutdowns at chip factories. As industries resumed operations, the demand for microchips skyrocketed, but the supply struggled to keep up. Here, we’ll take a closer look at how the microchip shortage has impacted the global auto industry.

How COVID-19 Changed the Game Rules

As a consequence of the shortage in 2020, automakers and dealers canceled existing orders for cars and stopped placing new ones. Such a market strategy was based on experience. During previous political, economic, and social crises, consumers stopped buying cars, and overall sales declined significantly. In addition, millions of employees have switched to remote work, so some car manufacturers didn’t think that people would soon have an urgent need for personal transport.

After the shock during the first months of the pandemic, the situation changed dramatically, and consumer demand for cars began to increase again. However, it was already too late: competition began in the electronics industry market because semiconductor chips are needed not only for cars but also for mobile phones, computers, and different household appliances.

At the same time, chip makers were facing new challenges as the pandemic disrupted established supply chains. It became more difficult to buy and deliver raw materials, which sometimes had to be brought not just from other countries but from other continents that found themselves in complete isolation. When production was relatively up and running, everyone was faced with pent-up demand for mobile phones and computers that was so high that chip makers simply couldn’t keep up with it. Since then, the manufacturers have been unable to properly manage the growing demand. As of today, things aren’t going well, even though it has been three years since the pandemic began.

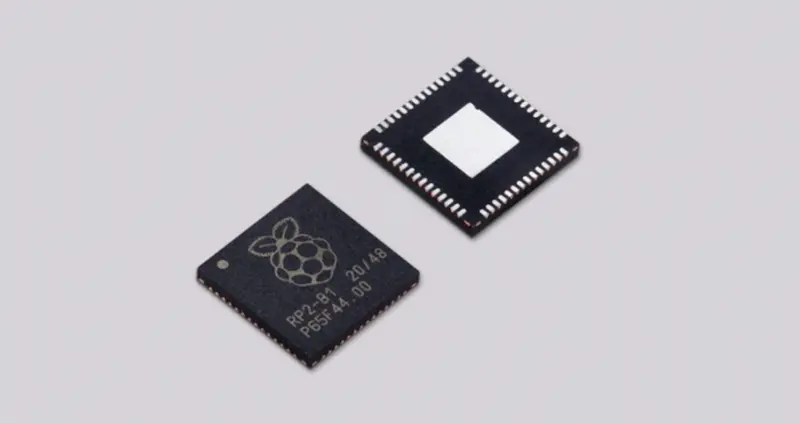

Why Chips Are So Important For the Automotive Industry

Semiconductor chips are used in a variety of components in modern vehicles, including engine management systems, infotainment systems, and advanced driver assistance systems. Because the auto industry is highly interconnected, the shortage of microchips had a ripple effect across the entire sector. As a result, the chip shortage has led to delays and production cuts in the auto industry, which in turn has led to a decrease in the supply of new vehicles.

If we speak about how the car manufacturer responded to the situation, market globalization caused significant consequences for the automotive industry. For example, when General Motors reduced its production due to the microchip shortage, it also impacted other automakers and their supply chains. This interdependence created a backlog for automakers waiting for microchips, which caused production bottlenecks and forced some factories to shut down temporarily.

Automakers such as Ford and Stellantis have been forced to suspend production temporarily due to the shortages. This decrease in production led to new car prices skyrocketing, as supply could not keep up with demand. Dealerships have been left with empty lots, and customers have had to wait longer than usual to get their vehicles delivered.

The impact of the microchip shortage on the global auto industry has been widespread. Many automakers, including General Motors, Ford, and Honda, have had to temporarily halt production at their factories in various parts of the world. Other companies, such as Toyota and Volkswagen, have had to reduce production and adjust their output schedules to cope with the shortage. The shortage has also led to higher prices for both new and used vehicles, as the decreased supply has led to increased demand. As for wrecked cars with intact electronics, such as cars with minor damage in the form of dents/scratches, their relevance has also increased because of parts.

The effects of the microchip shortage are likely to continue to be felt in the auto industry for some time. Automakers are working to secure additional supplies of chips, but it may take several months for the industry to return to normal production levels in 2023. In the meantime, consumers may continue to face higher prices and longer wait times for new vehicles, and automakers may see decreased profits as a result of the production cuts and delays caused by the chip shortage.

In the End

The microchip shortage has had a significant impact on the global auto industry, from creating production bottlenecks to forcing the suspension of production lines. The shortage has led to disruptions across the entire sector and has caused significant economic damage. While there is hope that the situation will improve over time as manufacturers increase their capacities, the microchip shortage has already made its mark on the auto industry for years to come.