Lithium Battery Safety: Ensuring Long Cycle Life Without Compromising Security

In an era driven by portable electronics, electric vehicles, and renewable energy systems, the role of lithium-ion batteries has become undeniably vital. These compact powerhouses have transformed the way we live, work, and travel. As we rely increasingly on these energy storage solutions, the need to strike a delicate balance between optimizing their cycle life and ensuring their safety has become paramount.

Understanding Lithium Battery Cycle Life

Lithium battery cycle life refers to the number of charge and discharge cycles a battery can endure before its capacity diminishes to a specified level. This metric is critical because it directly impacts the longevity and usability of the battery. Several factors influence the cycle life of lithium-ion batteries, including the depth of discharge (DOD), charge and discharge rates, temperature management, and the battery’s chemistry and design. For a comprehensive guide, click here to READ MORE.

- Depth of Discharge (DOD): The extent to which a battery is discharged affects its cycle life. Shallower discharges can prolong the battery’s life, as deeper discharges lead to more stress on the electrodes and electrolytes.

- Charge and Discharge Rates: Rapid charging and discharging generate heat, which can degrade the battery’s performance over time. Managing these rates can significantly influence cycle life.

- Temperature Management: Exposing lithium batteries to high temperatures accelerates their degradation. Proper thermal management, both during usage and storage, can help extend cycle life.

- Battery Chemistry and Design: The choice of battery chemistry and design impacts its inherent cycle life. Manufacturers often tailor these aspects to balance factors like energy density and lifespan.

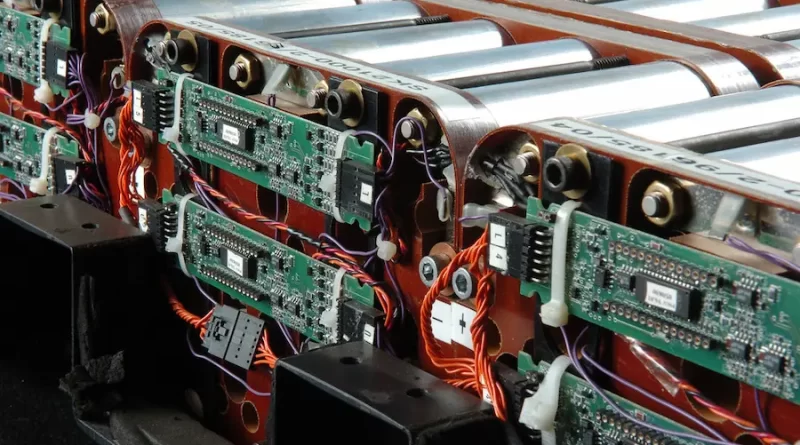

To enhance cycle life, certain strategies can be adopted. Optimal charging practices, such as avoiding high states of charge or discharge, can help mitigate stress on the battery. Battery management systems (BMS) play a crucial role in monitoring and controlling various parameters to ensure safe and efficient operation. Additionally, proper storage and maintenance practices, such as storing batteries at moderate temperatures and avoiding prolonged storage at full charge, can contribute to extended cycle life.

Ensuring Lithium Battery Safety

While cycle life is crucial, ensuring the safety of lithium batteries is non-negotiable. These energy storage devices have been associated with safety hazards, including thermal runaway, overcharging, short circuits, and mechanical damage. The potential risks are not to be taken lightly, especially as these batteries become integral to our lives.

- Thermal Runaway and Overcharging: Overcharging can lead to the build-up of gas within the battery, which can ultimately result in thermal runaway—a chain reaction of escalating heat and gas release. Manufacturers have focused on developing safer charging algorithms and voltage control mechanisms to mitigate this risk.

- Short Circuits and Mechanical Damage: Physical damage to the battery, such as punctures or external pressure, can lead to short circuits and potentially hazardous situations. Improved casing designs and impact-resistant materials help reduce the likelihood of these incidents.

- Internal and External Sources of Heat: High temperatures, whether from external sources or internal reactions, can trigger catastrophic events. Advancements in thermal management systems, such as phase change materials and improved heat dissipation pathways, play a pivotal role in maintaining battery safety.

Recent advancements in battery safety have been promising. Innovations in electrolyte formulations and the integration of flame-retardant materials and coatings have contributed to minimizing fire risks. Enhanced thermal management systems, including better heat dissipation and active cooling methods, have further bolstered battery safety.

Role of Regulatory Standards in Ensuring Safety

Ensuring lithium battery safety isn’t solely the responsibility of manufacturers. International regulatory standards and guidelines provide a framework that manufacturers must adhere to, ensuring that the products they bring to market meet specific safety criteria. These standards encompass aspects such as battery design, testing protocols, and performance thresholds.

- International Regulations and Guidelines: Organizations like the International Electrotechnical Commission (IEC) and the International Organization for Standardization (ISO) have established comprehensive safety standards for lithium batteries. These standards cover everything from design and manufacturing to transportation and disposal.

- Manufacturers’ Adherence to Safety Standards: Reputable manufacturers prioritize safety and often exceed regulatory requirements. Adhering to these standards not only ensures product safety but also fosters consumer trust.

Balancing Cycle Life and Safety

Striking the right balance between cycle life and safety is a complex challenge. While improving cycle life often involves pushing the limits of battery chemistry and design, maintaining safety requires a cautious approach. Fortunately, ongoing research and innovation have led to promising developments.

- Innovations in Battery Chemistry: Solid-state lithium batteries and silicon-anode batteries represent innovative approaches that offer both enhanced cycle life and improved safety. Solid-state batteries, for example, use solid electrolytes, reducing the risk of leakage and enhancing overall safety.

- User Education and Responsible Battery Use: Educating users about proper battery use is instrumental in maintaining both cycle life and safety. Manufacturers can provide guidelines for optimal charging practices, emphasizing the importance of avoiding extreme operating conditions.

Case Studies: Success Stories in Lithium Battery Development

Several companies have made significant strides in advancing lithium battery technology while ensuring safety and cycle life.

- Tesla’s Approach: Tesla’s commitment to battery safety and longevity is evident in its electric vehicles. The company employs advanced BMS and thermal management systems to optimize both cycle life and safety, contributing to the widespread adoption of electric cars.

- Consumer Electronics Innovations: Consumer electronics companies continuously innovate to provide longer-lasting and safer batteries for portable devices. These innovations range from efficient energy management systems to novel battery chemistries.

- Renewable Energy Storage Applications: In renewable energy systems, battery safety and cycle life are critical for grid stability. Companies developing energy storage solutions prioritize robust battery designs and management systems to ensure both longevity and safety.

Future Prospects and Emerging Technologies

As technology evolves, so does the landscape of lithium battery safety and cycle life enhancement.

- Evolving Battery Research: Ongoing research continues to uncover new materials, chemistries, and designs that hold promise for safer and longer-lasting batteries.

- Predictive Analytics and AI: Artificial intelligence and predictive analytics are increasingly integrated into battery management systems, offering real-time monitoring, early fault detection, and adaptive control strategies.

Conclusion

In a world driven by energy-demanding applications, lithium-ion batteries have revolutionized how we power our lives. Striving for both long cycle life and safety is not a trade-off but a challenge that demands innovative solutions. Manufacturers, regulators, and users must collaborate to ensure that lithium batteries continue to power our future, safely and efficiently. By staying informed, adopting responsible practices, and embracing emerging technologies, we can confidently embark on a future where our energy needs are met without compromising security.